-

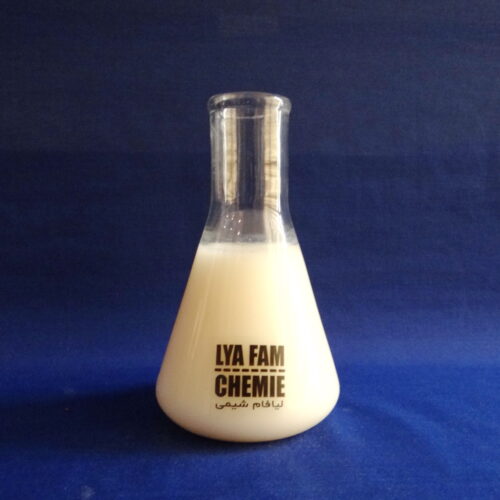

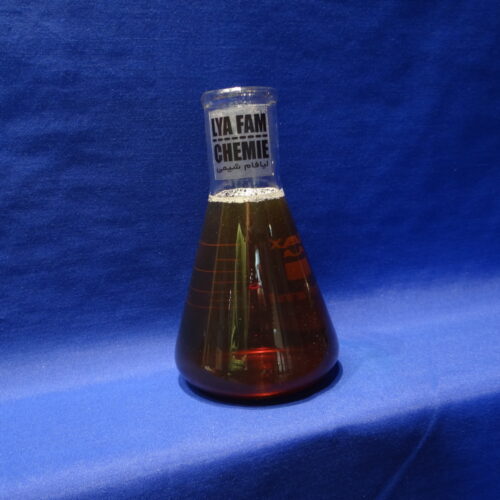

It is a concentrated poly-acrylate based lubricating agent and crease preventing agent for natural and synthetic fibres and their blends. The product is specially recommended when fabric is processed at low liquor ratio on machines with high shear forces. Due to its chemical nature, the product can be used in pre-treatment, dyeing as well as washing-off process.

-

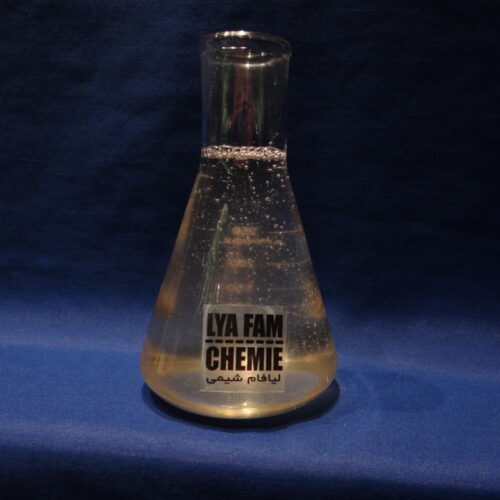

It is a silicone based defoamer suitable for all textile wet processing operations, where foam control is essential. It can be used in jets, overflow dyeing machines, package dyeing machines, winches, jiggers and in print paste. This product does not lead to any objectionable deposits on equipment or substrates due to its high stability.

-

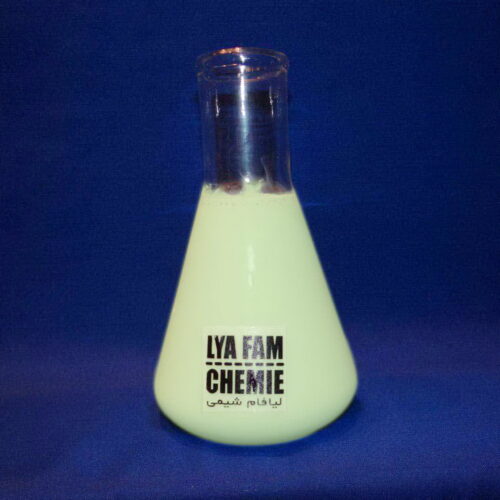

Antistatic is combination of fatty acid esters, special emulsifirer, antistatic and antistatic softener with compatible surface active agents. Due to its high antistatic property Antistatic prevents antistatic electricity in synthetic fibers. Besides, it brings brightness and loftiness to the fiber. It improves the moisture holding. It increase the fiber-fiber cohesion while decrease the fiber-metal friction. It does not cause malador and yellowing. It is compatible with all other nonionic substances. However, it does not compatible with anionic substances. It can be mixed with water at any ratio and easily washed off from fiber.

-

It is a concentrated organic softener which can be diluted to 1:10 to make ready to use economical softener for cotton yarn, hosiery, wool, silk and garments. Unlike conventional cationic softeners. This product does not affect whiteness since it is low yellowing type. Thus, it is ideal for finishing of light dyed material as well as washed denim garments which requires minimum shade change after fishing.

-

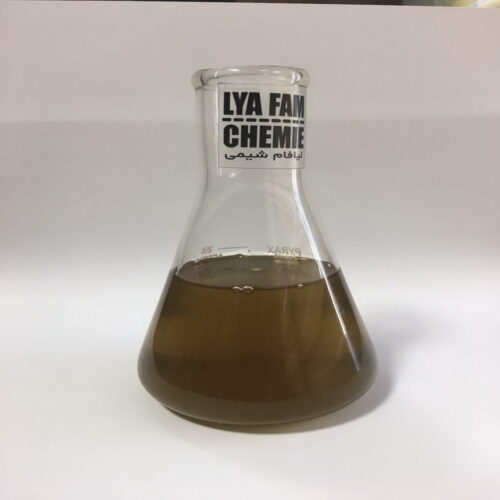

This product is specially developed concentrated high performance, dispersing agent for the production of level dyed shades on polyester with disperse dyes at high temperature by exhaust application. It possesses in-built dispersing action of polyester oligomer thereby reduces problems of lower rub-fastness in package dyeing and also clears oligomer residues from the machine. It is low foaming and highly affective even at low concentration in the dyebath.

-

This product is a special formulation for dyeing of reactive dyes a vat dyes by exhaust as well as pad application. It improves the solubility of reactive dyes under adverse conditions of dyeings such as low liquor ratio, poor quality of salt, hardness in water, poor solubility of dyestuff. Use of urea can be eliminated by addition of it. Hence, BOD values of effluent can be reduced drastically. It also act as a dyebath conditioner and levelling agent particularly for package dyeing.

-

This product is an excellent leveling and dispersing agent for dyeing of polyester fabric and its blends with disperse dyes and fluorescent whitening by HT process. It prevents filtration of dyestuff/optional brightening agent during dyeing in cheese dyeing and beam dyeing m/c. This product prevents deposition of dyes in m/c and on fabric. It can be used in alkaline dyeing of polyester (pH 9-9.5) with suitable disperse dyestuff.

-

Machine cleaner is an Alkylamineethoxylate solvent free product for the cleaning of textile, printing and dyeing machines, reduction clearing PES dyeing. This product resistant to alkalis, acids and electrolytes and hardwater in all usual concentrations machine cleaner is solvent free, hence no attach on rubber rolles, machine partor varnishes and compatible with anionic auxiliaries in diluted solutions; concentrated mixtures with anionic auxiliaries have to be checked d=for compatibility. This product have very high dissolving and dispersing capacity.

-

It is an enzyme based peroxide scavenger to remove residual peroxide at the end of bleaching or before reactive, Direct, Indigo, Solfour dyeing. The presence of peroxide during reactive, Direct, Indigo, Sulfur dyeing can lead to variation in shade, therefore it is important to eliminate residual peroxide before reactive, Direct, Indigo, Sulfur dyeing for consistent dyeing.

-

This product is specially designed formulation for removal of stubborn stains, particularly, loom oil stains from texturised polyester fabrics without hand spotting. It is also suitable for stain removal of polyester/cellulosic and polyester/wool blends since, it does not affect the cellulosic or wool component.

Due to excellent stability at high temperature and alkaline pH, it can be used in weight reduction of polyester.

-

This product is high power sequestering agent specially developed for scouring as well as bleaching of cotton, terry towel and polyester/cellulosic blends.

It has a high chelating action for calcium, magnesium and iron under alkaline conditions and high temperature. It is not only prevents precipitation of insoluble hydroxide and carbonates formed during scouring and bleaching, but also chelates iron impurities thereby preventing catalytic and pin-hole marks during peroxide bleaching.

It is also suitable for combine scouring and bleaching operation.

-

This product is specially designed formulation for removal of stubborn stains, particularly, loom oil stains from texturised polyester fabrics without hand spotting. It is also suitable for stain removal of polyester/cellulosic and polyester/wool blends since, it does not affect the cellulosic or wool component. Due to excellent stability at high temperature and alkaline pH, it can be used in weight reduction of polyester. It can be used in pre-washing without draining the bath.

-

It is an economical organic peroxide stabilizer for exhaust as well as continuous application of hydrogen peroxide bleaching of cotton and cellulosic blends. Apart from good peroxide stabilizing action it also chelates certain extent iron present either in the fiber or in the water.

It is also suitable for high temperature bleaching and high temperature combined scouring and bleaching of cotton & cellulosic blends.

-

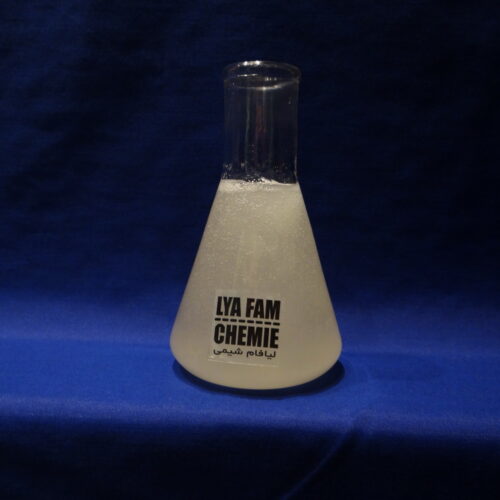

Wetting Agent is allow foaming, combination of anionic and non-ionic surfactants wetting agent. Under normal working conditions and in baths containing’s alkalis, it imparts excellent wetting and dispersing quality up to 12’Be. In caustic soda stable up to 20’Be. For said properties used is boiling, kier-boiling, bleaching, carbonization and milling processes. Used for removing greases, wax and spots. Knitted cotton and woven fabrics, processed with this wetting agent are improved for optimal hydrophility and whiteness. This product imparts excellent softness and fine touch.